- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

You may ask what the difference between palletized and depalletizing is. Palletizing involves putting goods or products onto pallets, while depalletizing refers to taking goods or materials off pallets. The process of depalletizing is harder because items can move around, leading to a higher likelihood of mistakes occurring.

| Process | Complexity Level | Error Rates | Operational Challenges |

|---|---|---|---|

| Palletizing | Moderate | Lower | Labor shortages |

| Depalletizing | High | Higher | Manual operations |

Manual pick-and-place jobs can cause mistakes during depalletizing. Items may not be stacked correctly, which can slow down operations. Understanding the difference between palletized and depalletizing is essential for improving your work efficiency.

Palletizing means putting products on pallets for safe keeping and shipping. Depalletizing is taking items off pallets for more work.

Depalletizing is usually harder than palletizing. Items can be in random places, so mistakes happen more often.

Using machines in both jobs makes things faster. Robots can move mixed items and fit different shapes. This helps people do less work and make fewer errors.

Picking the best way depends on what products you have. You also need to think about how fast you need to work, how much space you have, and how to keep people safe. Check what you need to make your work better.

Both palletizing and depalletizing help make moving products easier. They also help keep people safe and keep things running smoothly in warehouses and factories.

Palletizing is when you put products on a pallet. This makes it easier to move or store them. Warehouses and factories do this a lot. The main goal is to keep things safe and neat. This helps during shipping or storage. Sometimes, machines or robots help with palletizing. They are useful when you have many items to move fast.

Here is a simple way to understand palletizing:

Decide how to put goods on the pallet. Pick the right pallet and stacking way.

Get the items ready for stacking.

Put the items on the pallet in the order you planned. Make sure the weight is even.

Use straps or shrink wrap to keep things from moving.

Put a label on the pallet with important information.

Palletizing works for many products. You can stack boxes, bags, trays, or cases. This is good for food, drinks, heavy things, and other goods.

| Product Type | Packaging Format |

|---|---|

| Food and Beverages | Bags, Boxes, Trays |

| Heavy-Duty Products | Varying Shapes and Sizes |

| General Products | Display Cartons, Shipping Boxes |

Tip: The right palletizing steps help you save time and stop damage when moving things.

Depalletizing is the opposite of palletizing. You take items off a pallet. This gets them ready for the next step at work. Depalletizing happens in warehouses, distribution centers, or factories. Machines or robots can help with this job. They are helpful when you need to unload lots of items fast.

The depalletizing steps are usually like this:

Find out what kind and size of products are on the pallet.

Pick the best way to grab the items, like by layer or by case.

Move the items from the pallet to a conveyor or another spot.

Scan, label, or sort the items if needed.

Depalletizing works for many kinds of loads, just like palletizing. You can take off boxes, bags, trays, or cases. This is important for jobs in logistics, e-commerce, food and drinks, cars, and medicine.

Note: Palletizing and depalletizing both help you handle products safely and quickly, no matter what kind of packaging you use.

There is a big difference in how palletized and depalletizing work. Palletizing moves products forward in the process. You put items on pallets after they are packed. This gets them ready for storage or shipping. Depalletizing goes the other way. You take items off pallets to start the next job, like sorting or processing.

| Process | Direction of Material Flow | Description |

|---|---|---|

| Palletizing | Downstream | Happens after packaging, stacking items onto pallets for storage or shipping. |

| Depalletizing | Upstream | Means unloading items from pallets to begin more processing. |

The table above shows how each process fits into warehouse work. Both palletizing and depalletizing help move products, but they do it in opposite ways.

Depalletizing is usually harder than palletizing. When you stack items, you decide where everything goes. But when you depalletize, items may not be where you expect. Boxes can move during shipping, so it is hard to pick them up. Sometimes, items are packed too close together, making them hard to grab.

Items might be in strange spots on the pallet, making depalletizing tricky.

Boxes can move during shipping, so pickup spots are not always the same.

You cannot control how things are stacked, so depalletizing is harder.

Depalletizing often means dealing with pallets packed by others, which can be messy.

You may need tools like barcode scanners to find out where things are.

Items might not be spread out evenly, so mistakes can happen.

Stacking quality changes, so you must change your plan each time.

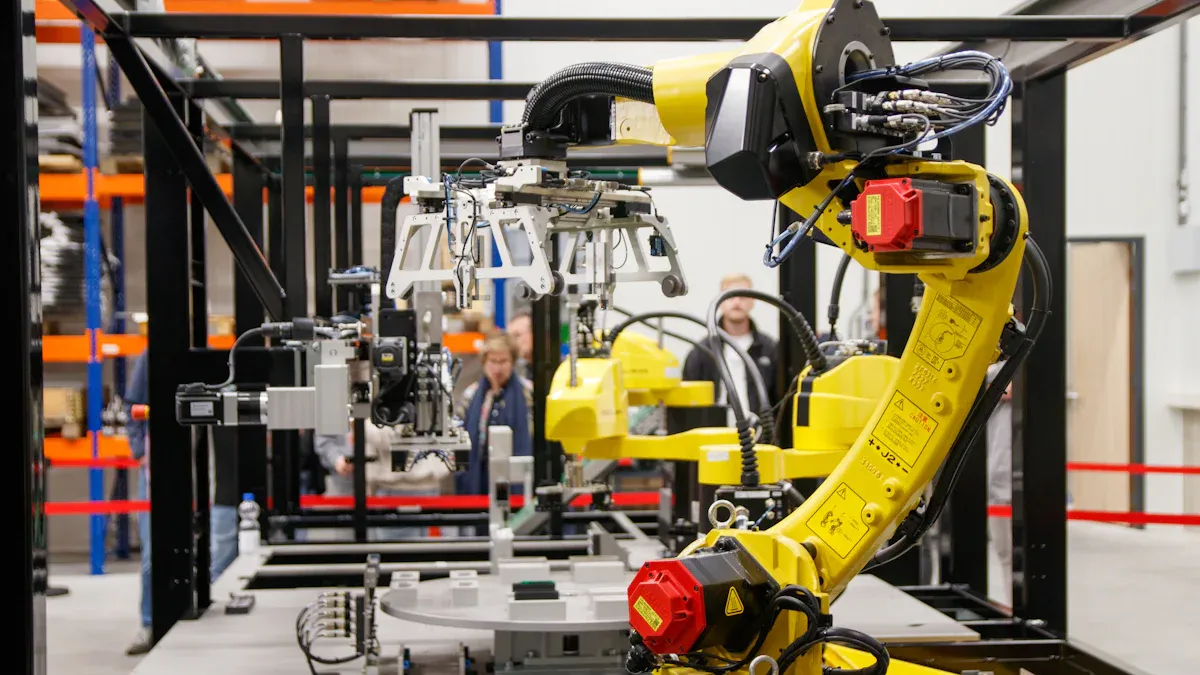

Robotic depalletizing uses smart cameras to fix these problems. These robots can see boxes and change how they grab them. They can handle mixed pallets, even if items are not straight. Robots help save money and make the work more reliable.

Tip: If you want fewer mistakes and faster unloading, try robotic depalletizing with AI and 3D cameras.

Warehouses use many machines for palletizing and depalletizing. Palletizing uses machines like case erectors, sealers, conveyors, and lift tables. Robots can stack items fast and in the right way. These robots use special tools to pick up many boxes at once. Some palletizers turn boxes so you can see the labels and build layers with sheets.

| Equipment Type | Description |

|---|---|

| Packaging Equipment | Has case erectors, sealers, palletizers, conveyors, lift tables, and more. |

| Automated Systems | Uses robots or machines for fast and correct stacking. |

| Robotic Palletizing | Uses special tools to pick up many boxes at once. |

| High-entry Palletizer | Turns boxes for label viewing and builds layers with sheets. |

| Gantry Palletizer | Picks up many boxes with special tools and moves them with servo motors. |

Robotic depalletizing machines have smart features. They can pick up many items at once and change speed and height by themselves. They can spot fallen boxes or slip sheets. These robots use AI and 3D cameras to sort items and check for empty pallets. They can handle tall and heavy pallets without needing new programs. These machines help work go faster and make fewer mistakes.

| Feature/Benefit | Description |

|---|---|

| Increases throughput | Picks up many items at once when possible |

| Constant pallet mode | Works faster when handling the same kind of pallets |

| Handles tall pallets | Can work with pallets up to 8 feet tall with the same items |

| Automatic speed adjustment | Handles items up to 80 pounds safely without new programs |

| Automatic height adjustment | Makes work faster and smoother |

| Box on ground detection | Finds fallen boxes to stop delays |

| Slip sheet detection | Finds and handles slip sheets automatically |

| Empty pallet detection | Starts new pallets or tells workers to change them |

Note: Robotic depalletizing uses smart sensors and cameras to handle items in random spots and make work better.

Many industries use palletizing and depalletizing. Palletizing is used when sending goods out. Food and drink companies use robots to stack cases of drinks. This keeps products safe and fresh. Electronics makers, like Apple, use careful palletizing to protect fragile items. Car parts need strong straps and bins to stay safe. Medicine companies use palletizing to keep things clean and follow rules. Stores and online shops build pallets to fit delivery trucks and save space.

Food and Beverage: Companies like Coca-Cola use robots to stack drink cases.

Electronics: Apple uses careful palletizing for things like iPhones.

Automotive Parts: Strong straps and bins are used for car parts.

Pharmaceuticals: Palletizing keeps medicine safe and clean.

Retail and E-commerce: Big stores build pallets to fit delivery plans.

Depalletizing is important when goods come in. Fast supply chains need quick depalletizing to keep things moving. Doing it by hand is hard and mistakes can happen, so many companies use robots now. Robots make depalletizing faster and more accurate. Automation helps in warehouses, online shopping, food and drink, and healthcare.

Fast supply chains need depalletizing for speed and flexibility.

Doing it by hand is hard and mistakes can happen.

Robots in depalletizing mean less hard work and better results.

You can see the main differences between palletized and depalletizing in these examples. Palletizing gets goods ready to ship. Depalletizing gets them ready for the next job. Robots help a lot in modern warehouses by handling tricky loads and making work smoother.

There are big differences in how machines help with palletizing and depalletizing. Palletizing uses machines to stack items that look the same. This makes stacking fast and easy. Robots follow a plan to put things in order. You get quick and steady results.

Depalletizing is harder for machines. Items might be stacked in random ways. Sometimes boxes move around or shift. Machines must change how they work each time. This can slow down the process. Still, both automated systems help save time. They also mean people do less heavy lifting. Using these machines saves money. Workers can do other important jobs. Fast machines help you finish orders quickly.

| Factor | Palletizing | Depalletizing |

|---|---|---|

| Material | Objects are typically uniform and predictable. | Objects may be stacked inconsistently, complicating handling. |

| Arrangement | Specific placement plans are often established. | External factors lead to unpredictable arrangements. |

| Speed | Critical to maintain production flow. | Important, but less critical than material and arrangement. |

Tip: Using automated palletizing and depalletizing helps you work faster and make fewer mistakes.

Palletizing and depalletizing both try to make moving goods easier. They help keep products safe and stop mistakes. These steps make sure things move smoothly in your warehouse or factory. Automation also keeps workers safe from lifting heavy things.

| Goal | Description |

|---|---|

| Streamlining Handling | Both processes aim to simplify the movement of goods within the supply chain. |

| Boosting Efficiency | They work together to enhance overall operational efficiency. |

| Reducing Errors | Consistent handling minimizes mistakes and protects product integrity. |

| Maintaining Flow | Essential for ensuring a steady flow of goods in production and distribution. |

You also save money and make jobs better for your team. Automation lets workers do tasks that matter more. The workplace is safer and people get hurt less. These goals show why both processes are important for your business.

When you pick between palletizing and depalletizing, think about your work process. Look at what kinds of products you have. Think about what your business wants to achieve. First, decide how fast you need things done. Regular depalletizers work quickly. Robotic depalletizing is more flexible and accurate. If your products are different shapes and sizes, robots handle mixed loads better than old machines.

Check how much space you have on your floor. Old machines need more room. Robotic depalletizing systems fit in smaller spaces. Safety is important, too. Robots need safety cages. They can work where people do not go much. Your plant layout and money also matter. Cheaper models cost less. High-level models are good for unloading from above.

Here is a table to help you compare:

| Criteria | Description |

|---|---|

| Speed | Robotic depalletizing is flexible and accurate, but sometimes slower than regular models. |

| Product Types | Robots handle mixed packaging better. |

| Floor Space | Robotic systems fit in small areas. |

| Safety | Robots need safety cages. |

| Budget | Cheaper models are easier to install. |

| Flexibility | Robots change for different products and loads. |

Think about the type, shape, and weight of your products. Heavy or strange-shaped items may need special robot arms or cameras. If your products have barcodes or QR codes, you may need a depalletizing system that can scan and sort them.

Use palletizing when you want to send goods out of your warehouse or factory. This keeps your cargo safe and makes shipping easier. Palletizing is best for long trips and when you need to put small packages together. Standard pallet sizes help you load and unload trucks fast.

Use depalletizing when you get goods and need to get them ready for the next step. Robotic depalletizing is best for many types of products or mixed pallets. It helps you work faster and make fewer mistakes. If your products are different shapes or have special labels, robots can scan and sort them easily.

Tip: Always pick what matches your work process, product types, and space. The right choice helps you save time, make fewer mistakes, and keep your team safe.

Now you know how palletized and depalletizing are not the same. Palletizing means stacking items so they travel safely. Depalletizing is when you take items off for the next job. Each task has its own problems and needs special machines.

Palletizing tries to keep things steady and save space.

Depalletizing must handle items that are not always in the right spot.

To pick the best way:

Look at what products you have and how you work.

Think about using machines to go faster and stay safe.

Choose the system that fits your needs.

Understanding palletized and depalletizing helps you work better and make fewer mistakes.

Palletizing helps make shipping and storage simple. It keeps products safe and neat. You can move many items together. This saves time and stops damage.

Depalletizing is harder because items can be in random spots. Boxes might move around when shipped. Workers or robots must change how they pick things up. This can lead to more mistakes.

Robots can do both palletizing and depalletizing. Machines stack and unstack items fast. Automation means less hard work and better accuracy.

Food, retail, e-commerce, automotive, and healthcare all use these processes. Warehouses and factories need them every day.

Tip: Think about your products, how you work, and your space. Robots are good for mixed loads. Regular machines work for items that look the same. Pick what fits your needs best.